Dongguan Caiyide New Material Co., Ltd. specializes in the production of three-dimensional curved surface coating film (water transfer film) and the design and development of new version graphics!

Mobile Website No Public

No Public Applets

Applets

Dongguan Caiyide New Material Co., Ltd. specializes in the production of three-dimensional curved surface coating film (water transfer film) and the design and development of new version graphics!

Mobile Website No Public

No Public Applets

Applets

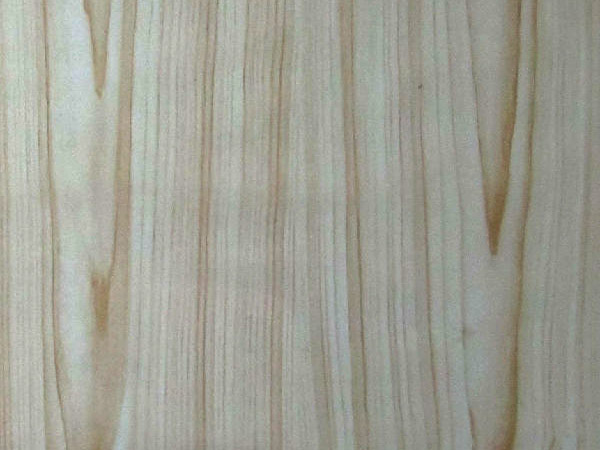

Everyone is searching:Thermal transfer effect、Water transfer film paper、Marble water transfer film、Wood grain water transfer film、Camouflage water transfer

Water transfer film During the printing process, the product should be kept clean and static electricity should be removed before applying the water transfer film. The transfer tank should be clean when rushing the water, there should be no floating impurities left on the water, and the residual ink film should not float on the water surface. When placing the water transfer stamp coating film, you should recognize the front and back of the film clearly when placing the film. You can test it with a little water with your hand. Put the sticky side on the water, but be careful not to accidentally splash the water. water transfer film. Pay attention to the film release angle (30 to 40 degrees inclination). At the beginning, straighten the water transfer pad printing coating film and push it from one side of the water transfer tank to the other side. Be careful not to generate air bubbles. If there are air bubbles or film side rolls When starting, you must press or blow by hand to blow off the air bubbles.

The production process of the water transfer stencil roller: 1. The production of the printing plate substrate. The material of the printing plate substrate is generally seamless steel pipe, and a few are made of aluminum material. 2. For the copper plating treatment of the printing plate roller, no matter whether the substrate of the printing plate roller is steel or aluminum (as long as it can meet the requirements), before making the plate-making copper layer, a pre-plating layer should be plated on the surface of the newly processed base roller. , there are several methods to choose from. Such as nickel plating, cyanide copper plating. 3. Original (or design) image file production, understand the customer's requirements, whether to copy the original or redesign on the basis of the original, and then scan the original, requiring the scanned image to be clear, the color as close to the original as possible, and the text lines are clear There should be no phantom, the size should not be deformed, etc., and then use professional pattern processing software to produce and process according to customer requirements and gravure characteristics. 4. For the electronic engraving of printing plate images, the Swiss imported engraving machine is used. After the image files are produced, the image files are RIPed and then operated on the electro-engraving workstation. Try carving, carving.