Dongguan Caiyide New Material Co., Ltd. specializes in the production of three-dimensional curved surface coating film (water transfer film) and the design and development of new version graphics!

Mobile Website No Public

No Public Applets

Applets

Dongguan Caiyide New Material Co., Ltd. specializes in the production of three-dimensional curved surface coating film (water transfer film) and the design and development of new version graphics!

Mobile Website No Public

No Public Applets

Applets

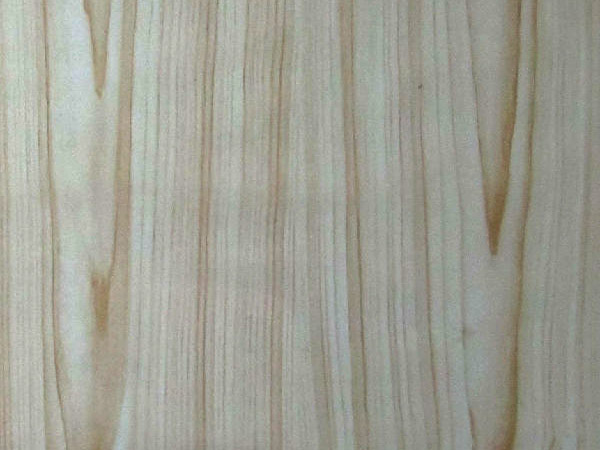

Everyone is searching:Thermal transfer effect、Water transfer film paper、Marble water transfer film、Wood grain water transfer film、Camouflage water transfer

Water transfer filmThe main process and basic process? Water transfer film: Water transfer is also called curved surface water coating. Its function is to treat the surface of irregular objects with three-dimensional curved surfaces - it belongs to the overall printing of the surface. Use pure natural patterns, such as mahogany, marble, jade, leopard skin, stripes, etc. After the object is processed, the color and luster are vivid and the image is lifelike.

Achieving the effect of mixing the real with the fake. Completely change the surface texture of the object, and the processed product appreciates greatly. Scope of application: automotive supplies: instrument panel, control panel, tissue box, cup holder, disk rack, rear view mirror frame, operating handle, car lock, etc.; electronic products: telephone, pager, video recorder, audio, remote control, mouse , clocks and other room supplies: sofas, coffee tables, cabinets, chandeliers, ashtrays, vases, display containers, etc.; daily fine products: luggage decorations, tableware handles, glasses brown, pens, pen barrels, desk calendar stands, art picture frames, Rackets, accessories, cosmetic pens, cosmetic boxes, etc.; Interior building materials: doors and windows, floors, wall panels, etc. Water transfer technology

It is known as a relatively environmentally friendly technology, and it is also the latest efficient printing production, probably related to his separation from the ink in the printing process. Water transfer uses water pressure and activator to dissolve and transfer the peeling layer on the water transfer carrier film. The basic process is:

1) Film printing: printing various patterns on the polymer film;

2) Spray primer: Many materials must be coated with a layer of adhesive, such as metal, ceramics, etc. If you want to transfer different patterns, you must use different background colors, such as wood grain basically use brown, brown, soil Yellow, etc., the stone pattern is basically white, etc.;

3) Extension of the film: let the film lay flat on the water surface, and wait until the film is stretched flat;

4) Activation: The pattern of the transfer film is activated into an ink state with a special solvent (activator);

5) Transfer: use water pressure to print the activated pattern on the printed object;

6) Washing: wash the remaining impurities of the printed workpiece with water;

7) Drying: Dry the printed workpiece, and the temperature depends on the elemental properties and melting point of the material;

8) Spray paint: spray transparent protective paint to protect the surface of the printed object;

9) Drying: Dry the surface of the object that has been sprayed with topcoat.